Contract Manufacturing & Fabrication Specialists

Our core mission is to provide specialist engineering and contract manufacturing services utilising our unique capabilities to add value to our clients’ supply chains. As part of one of Europe’s largest fabrication and contract engineering groups, we operate from our Rotherham-based Head Office and primary manufacturing facilities, boasting 367,000 sq. ft. of factory space set amidst 13 hectares of private land.

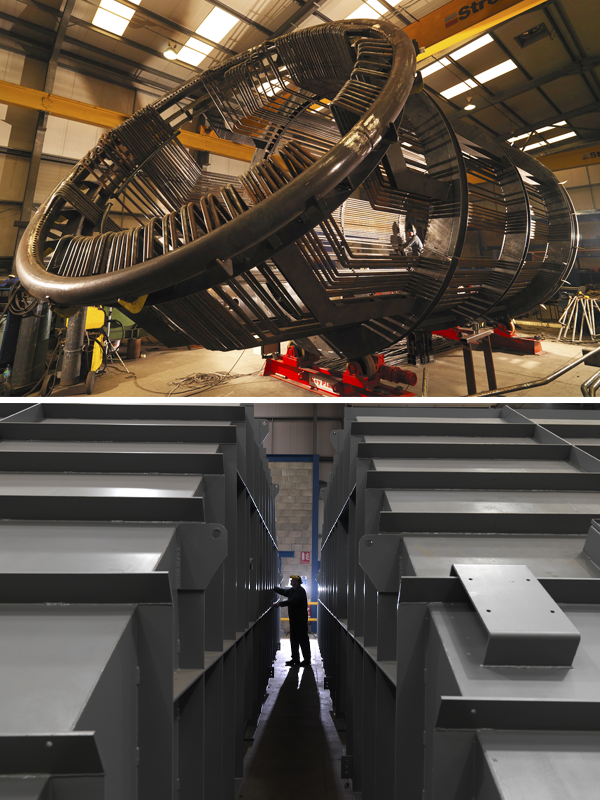

MTL Advanced process in excess of 25,000 tonnes of material annually, handling all sizes and types of work in a wide array of materials including carbon steel, aluminum, stainless steel, high strength steel, weathering steel , armoured steel and titanium to name but a few. Our state-of-the-art facilities can effortlessly cut 14m long x 3.3m wide parts, producing complex forming components with up to 0.5 degrees of accuracy using the world’s largest robotic press brake.

Our continued investment of CNC machining centres enables prompt processing of customer requirements. We provide coded welding and fabrication services, accredited to ISO EN 3834 Part 2 status, in our 150,600 sq. ft fabrication space with 17 x modern robotic welding systems. Our customers, spread across the globe, rely on us for our expertise and knowledge of specialist materials such as wear-resistant steels, high-strength steels, and armor plate-manufactured components and fabrications.

Our Sectors

Defence and Security

Recycling

Construction & Quarrying

Rail

General Engineering

Agricultural

Advanced Manufacturing Centre

MTL Advanced, a leading UK engineering and manufacturing firm, has announced a £10 million investment to build a new 67,000 sq. ft. Advanced Manufacturing Centre in Rotherham, set to open in November 2024. This expansion follows the award of long-term, multi-million-pound contracts, aiming to enhance production capabilities and drive future growth.

The investment includes cutting-edge equipment, such as a large-format press brake and robotic welding centres, and will create 100 new jobs, including 24 additional apprentices, boosting local economic growth.

General Manager Karl Stewart emphasised that this expansion reinforces MTL’s dedication to quality, customer service, and long-term stability in the industry.

Capabilities

Materials

Strenx®

MTL is one of the largest processors of components manufactured from Strenx® Steel. Our skilled workforce has many years’ experience working with this material.

Hardox®

MTL Advanced is one of the largest suppliers of components manufactured from Hardox®. Our skilled work force has many years’ experience of working with this material.

Armox®

Armox® Protection Plate steels are highly acclaimed for effectively safeguarding individuals and valuable assets in various challenging environments around the globe.

Strenx®

MTL is one of the largest processors of components manufactured from Strenx® Steel. Our skilled workforce has many years’ experience working with this material.

Hardox®

MTL Advanced is one of the largest suppliers of components manufactured from Hardox®. Our work force has many years’ experience of working with Hardox.

Corten Steel®

Corten Steel (Cor-ten®) is a low-alloy, high-strength outdoor steel and is one of the groups of ‘Weathering Steels’ meaning it is designed to develop a rusty aesthetic once left to weather.

Armox®

Armox® Protection Plate steels are highly acclaimed for effectively safeguarding individuals and valuable assets in various challenging environments around the globe.

Armoured Materials

MTL Advanced utilises advanced armoured materials, including steel, titanium, and aluminium, to provide robust protection for a wide range of applications across various industries.

High Strength Steel

We have partnered with leading high strength steel manufacturers such as SSAB and Thyssenkrupp for 25+ years and are experts at processing & fabricating materials with exceptional hardness.

Corten Steel®

Corten Steel (Cor-ten®) is a low-alloy, high-strength outdoor steel and is one of the groups of ‘Weathering Steels’ meaning it is designed to develop a rusty appearance once left to weather.

Armoured Materials

MTL Advanced utilises advanced armoured materials, including steel, titanium, and aluminium, to provide robust protection for a wide range of applications across various industries.

High Strength Steel

We have partnered closely with leading high strength steel manufacturers such as SSAB, Arcelor Mittal, and Thyssenkrupp for over 25 years and are experts at processing and fabricating materials with exceptional hardness.

Quality Assurance

MTL Advanced has attained certification in all major quality management standards, including ISO 9001:2015, EN 3834-2, ISO 45001, ISO 14001, EN 1090, ISO 15085, APQP 2110, and is also accredited by the German Bundeswehr and holds the Cyber Essentials Plus Certification. Annually, we process approximately 30,000 tonnes of material and are equipped to handle a wide range of projects, from carbon steel to aluminium.

Engineering Apprenticeships at MTL Training Academy

Since 2015, we have been opening doors for local individuals to gain valuable skills for a successful career in engineering. Our state-of-the-art Academy, located in Rotherham, is proud to be a part of WEC Group’s Training Academy based in Darwen, Lancashire, to provide a wide range of five-year engineering apprenticeships. From Welding & Fabrication to Laser & Press Brake Operations, CNC Machining, and Business Administration, we have it all covered.

Becoming an apprentice at MTL offers you the opportunity to work alongside experienced engineers, deepen your understanding of the industry, and earn both a qualification and a lifelong trade. Furthermore, upon completing your training, you will receive a guaranteed job offer, ensuring a seamless transition into a rewarding career.

MTL Careers

Recent News Posts

Part of WEC Group

WEC Group is the UK’s largest engineering & fabrication company, with over 900 staff and 700,000+ square feet of manufacturing space spread across 15 manufacturing sites in Lancashire, Yorkshire, Merseyside, West Midlands, and Dorset.

Headquartered in Darwen, Lancashire and established for over 45 years, WEC Group specialises in laser /waterjet / plasma cutting, coded welding & fabrication, CNC machining, heavy engineering, powder coating, and wet painting. The company services over 2500 engineering clients every year across a broad range of sectors like Nuclear, Aerospace, Rail, Defence, Security, Automotive and Construction to name but a few.

WEC Group are known for their commitment to quality, innovation, customer service and their commitment to training the next generation of world class engineers through their award-winning Apprentice Training Academy.

MTL Advanced became part of WEC Group in 2015 and our combined expertise has enabled us to build a strong and sustainable order book, ensuring long-term stability for MTL and the skilled workforce that supports us.